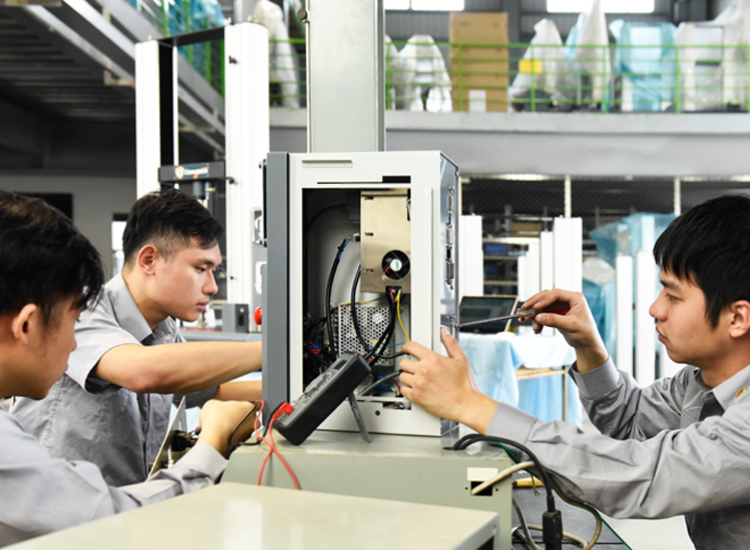

技術領先,獨創的設計吸引眾人目光, 品牌的獨特性及品質非他人所能仿製

QC-622H表面硬度磨耗試驗機為廣錸儀器研發成功銷售近2年的機款,使用客群包含國內知名滑鼠大廠、國外手機殼大廠,以及工研院實驗室單位。

QC-652B/C/D/E

熔融指數試驗機

QC-639V/W

衝擊試驗機-電子式

QC-317F

耐水度試驗機-電子式

QC-548M1F-S

拉力試驗機

QC-548D2-S

拉力試驗機

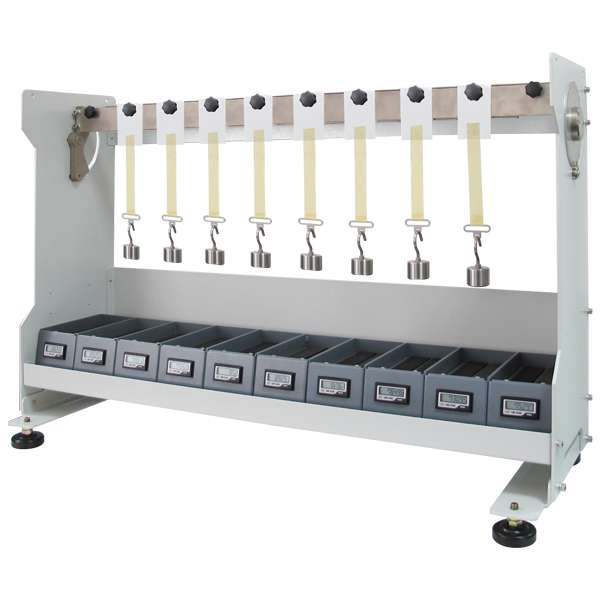

常溫型多角度膠帶保持力試驗機QC-801D

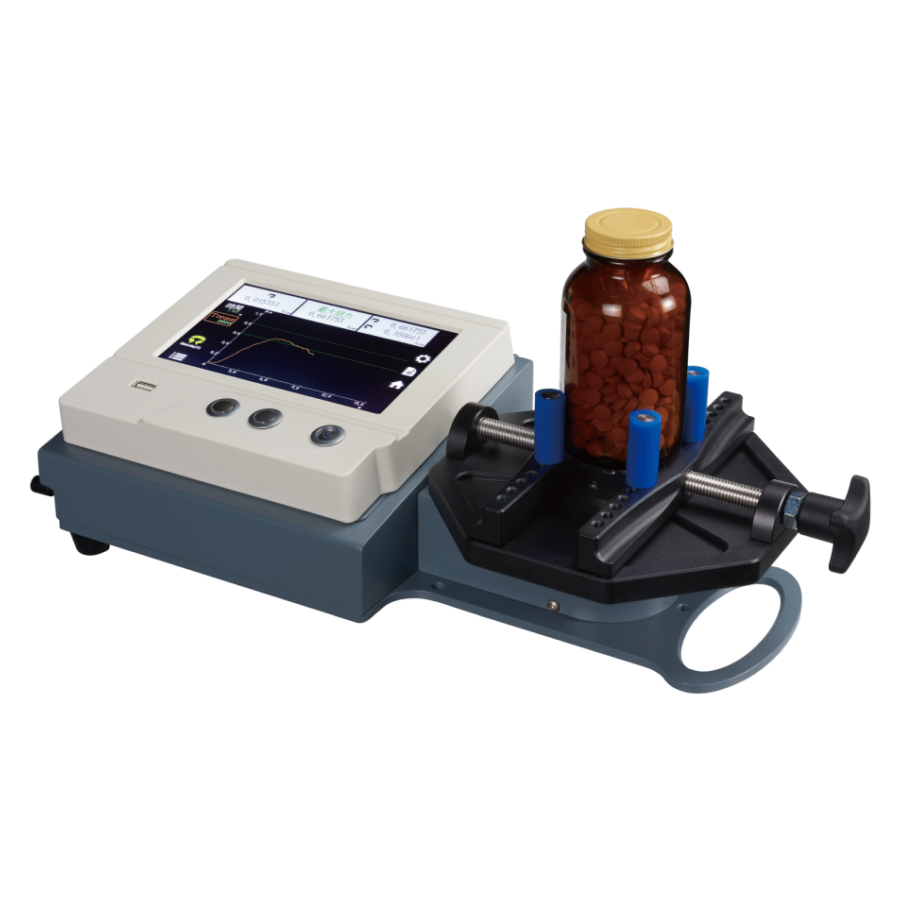

QC-41111

扭力試驗機-可程式型

QC-674A

熱壓成型機-可程式

QC-621N

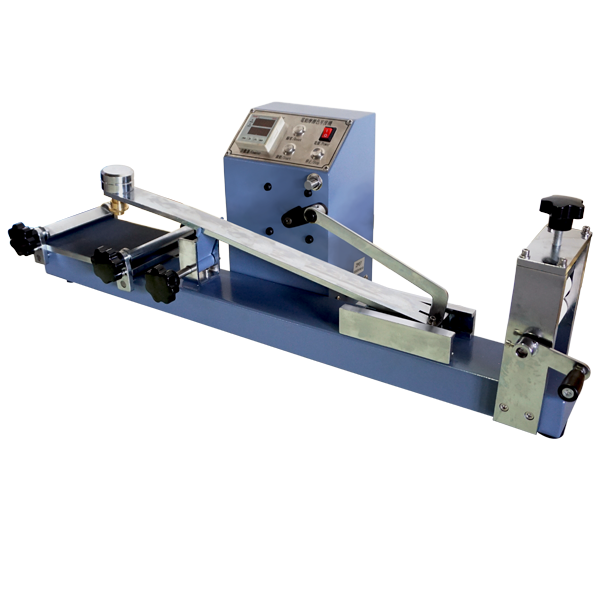

電動摩擦色牢度試驗機

QC-548M2F-S

拉力試驗機

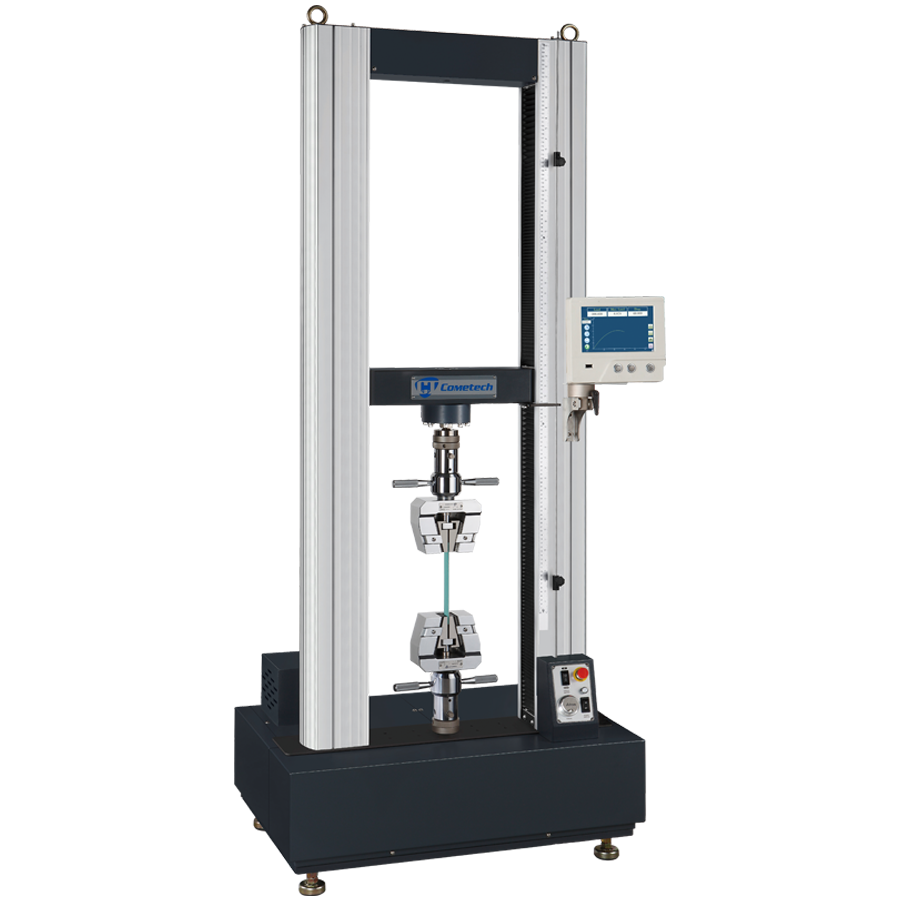

QC-501M2F

萬能材料試驗機

QC-505M1F

萬能材料試驗機

QC-548M1F-M

拉力試驗機

QT-010

扭力試驗機-手動型

QC-958

容量300kN

液壓拉(壓)力試驗機-電腦式

QC-41110

扭力試驗機-電動型

QC-528D3

拉力試驗機

QC-116D

自動型破裂強度試驗機

服務

測試規劃, 教育訓練, 維修服務, 校正與認證, 客製服務, 更新與升級

透過初步測試,將由專業工程師針對測試過程及結果進行設備評估,為您的測試規劃最佳機型,使您免於不知使用何機台、不知如何進行測試之困擾,我司提供完善規劃滿足您各式需求。

READ MORE

由具豐富經驗的專業工程師到場親自培訓,提供完整教育訓練內容,使您的操作人員、開發人員從新手到專家

READ MORE

機台於保固期間內提供免費維修,保障完善的售後服務。本公司良好的ERP倉儲系統,產品在售後10年內皆可快速取得常備維修所需的零件

READ MORE

我司產品取的TUV之CE認證,遵從CE規定且遵循各種標準規範設計製作。依照規範標準來標定各式儀器,皆透過專業工程師高規格精密校正

READ MORE

我司軟體採自主性開發,由研發團隊獨立開發自有軟體程式,具有高度整合能力及擴充性,可以新增分析項目滿足各種不同的測試需求。

READ MORE

我司可以幫助您評估升級最新軟體與控制器,可用於升級舊款機型或針對非我司機型進行改機,使您舊有的機台重新恢復使用並提升效能及延長

READ MORE

最新消息