Description

Digital Bursting Strength Tester is used for testing the bursting resistance for samples such as base paper, corrugating paper, leather, synthetic leather. This tester is a digital type that features automatic compensation mechanism and sensor calibration to obtain a more accurate test result. The real-time force graph shows current status in various units for user’s choice, facilitating user’s data reading.

Conform to Standards

- ASTM D2210

- ISO 2759

- GB/T 6545

- JIS P8112

- JIS L1018

- TAPPI T403

Industry

Textile, Paper, Packaging

Catalog Download

QC-116 Digital Bursting Strength Tester

Testing Video

Specifications

Type

High pressure/ Low pressure/ Textile

Test speed

High pressure:170 ± 15 ml/min

Low pressure:95 ± 5 ml/min

Textile:98 ± 4 ml/min

Pressure display

By digital touch screen

Capacity

75 kg/c㎡

Platen diameter-Upper

High pressure:31.5 ± 0.05 mm

Low pressure:30.5 ± 0.05 mm

Textile:30.5 ± 0.05mm

Platen diameter-Lower

High pressure:31.5 ± 0.05 mm

Low pressure:33.1 ± 0.05 mm

Textile:30.5 ± 0.05mm

Gear position

Pressurization, neutral, return

Features

1. Using flow switch, and can switch to different speed of pressurization

2. Equipped with a 7-inch touch screen, and show real-time pressure and bursting time

3. Data exportable to USB

Dimension

53 x 33 x 58 cm

Weight

60 kg

Power

Single phase 110~240VAC,5A

Accessories

Rubber film-low pressure

This ancessory for the bursting strength test is placed under the test specimen plate. After pressurization, the glycerin will hold up the rubber film and then break the test specimen.

This is a test consumable that will be fouled, fatigued or broken when used for a period of time and will need to be replaced if necessary.

Note: Low pressure rubber film is applicable to the range 0~10kgf/c㎡

Rubber film-high pressure

This accessory for the bursting strength test is placed under the test specimen plate. After pressurization, the glycerin will hold up the rubber film and then break the test specimen.

This is a test consumable that will be fouled, fatigued or broken when used for a period of time and will need to be replaced if necessary.

Note: High pressure rubber film is applicable to the range 6~75kgf/c㎡

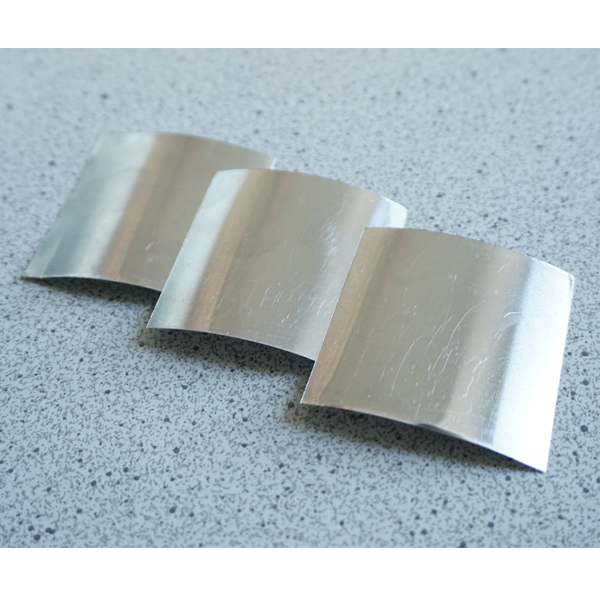

Aluminum foil

Standard sheet for calibration

Regular use of standard aluminum foil to check the condition of the testing machine. If the deviation is too large, it is recommended to replace a new rubber film.

Printer (optional)

Able to directly print out results

Related Machines

Related Services

-

Test Planning

Specialists would evaluate the preliminary testing result, choosing the best machine for your test planning. We will provide complete solutions which make you free of worrying about the unknown machines.

READ MORE

-

Training

The professional engineers with rich experience will personally train and provide complete training content. Your operators and developers can learn the technical skills of various material testing machines from novice to expert.

READ MORE

-

Maintenance Service

We provides free maintenance during the warranty period to ensure perfect after-sales service. Our ERP warehousing system makes users quickly obtain the required parts for standing maintenance within 10 years after the sale.

READ MORE

-

Calibration & Certification

Our company received CE certification from TUV. From design to manufacturing, all the products follow the CE standard rules. A high-level calibration is utilized to ensure the accuracy and stability.

READ MORE

-

Customize Service

The software is self development. R&D team independently develops its own software programs which has high integration capability and scalability to add new analysis items and meet various testing needs.

READ MORE

-

Update & Upgrade

We can help you update the software and hardware. Old model upgrading is also available, which could improve the efficiency and extend the machine service life.

READ MORE