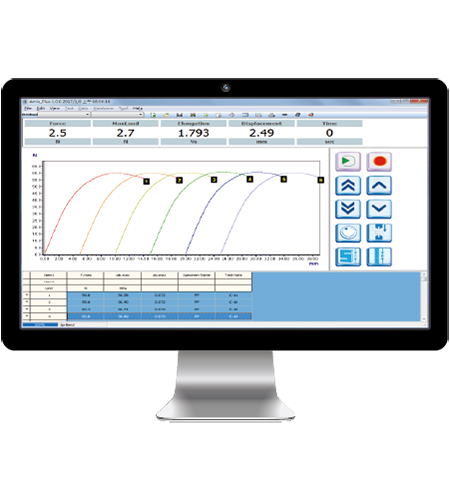

1.Data sample rate faster can be set up to 1200 Hz

2.Operation method: By keyboard and mouse control test, can also through up and down button to adjust the fixture position.

3.Software has multi-languages with Chinese, English display.

4.Operating mode: TCP / IP interface, two-way transmission, the computer directly control the machine action

5.Compatible with Window 8 /10 system

6.Can import multiple test data display simultaneously.

7.Unit selection can be Metric unit and Imperial units.

8.Form flexibility, self-planning information analysis.

9.Test Screen can be selected data display, graphic display or simultaneous display.

10.Graph X-Y axis physical quantity adjustment, graph-specific mark, interval mark, slope and so on.

11.Data name can be self-set and can self-defined formula.

12.Test tensile, compression, bending, creep and other tests.

13.Data processing: store, call, list, statistical comparison, etc.

14.Variety of test actions, ex. creep, constant tensile (compression)...

15.Support multiple sets of I / O signals, increase testing mechanism.

16.Modularization of specimen setting, providing easy to set specimen.

17.Software protection: Overload, over -displacement, over-time protection

18.Key data capture, can set the upper and lower limits of test data specifications.

19.Modularization of test conditions to reduce artificial setting negligence and error.