Description

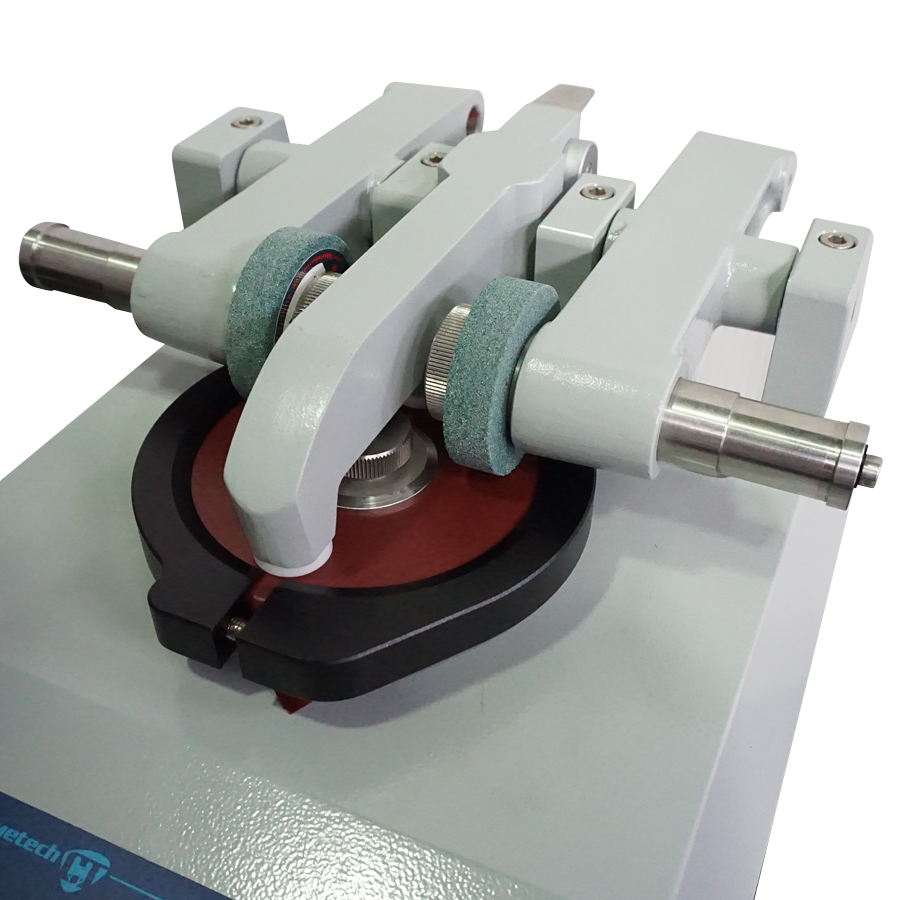

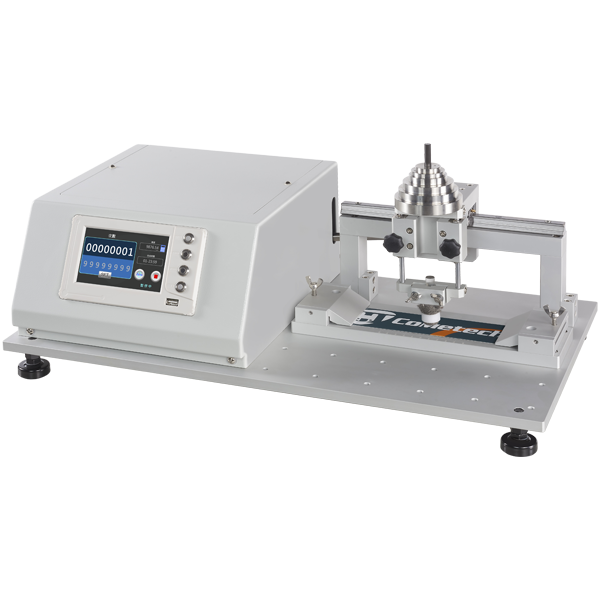

This equipment is designed for abrasion testing of various materials such as paper, textiles, plywood, flooring, glass, rubber and plastics. The specimen is fixed on the clamping area with a corresponding fixture. Depending on the testing requirements, users can select different abrading wheels, and additional weights can be mounted on both sides of the abrading arm to increase the testing load.

The tester allows users to set abrasion cycles and evaluate wear resistance after testing. During the test, the vacuum system is automatically activated to remove debris generated by abrasion.

Conform to Standards

- ASTM D3384

- ASTM D1175

- ASTM D1044

- ASTM D4060

- TAPPI T476

- ISO 9352

- ISO 5470-1

- JIS K7204

- JIS A1453

- JIS K6902

- JIS L1096

- JIS K6964

- DIN 52347

- DIN 53109

- DIN 53754

- DIN 53799

Industry

Rubber, plastic, textile, cloth, paper and construction material

Application

Abrasion Test

Catalog Download

QC-619C Abrasion Tester

Specifications

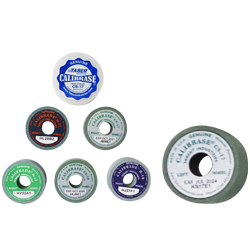

Abrading wheels

Diameter 2 inches, thickness 1/2 inch

Rotational speed

Adjustable from 50 to 100 RPM ±2%

(default: 60 RPM)

Test load

250g, 500g, 1000g

Counter

1-99,999,999 counts,

presettable with automatic stop

Specimen size

Ø110 mm, center hole Ø7.5 mm

Thickness: 1-6 mm, applicable to both flexible and rigid materials

Dimension

42 × 32 × 45 cm

Weight

23 kg

Power

Single-phase, 100-240V ; 50/60 Hz

Accessories

Gasket, nut

Sandpaper

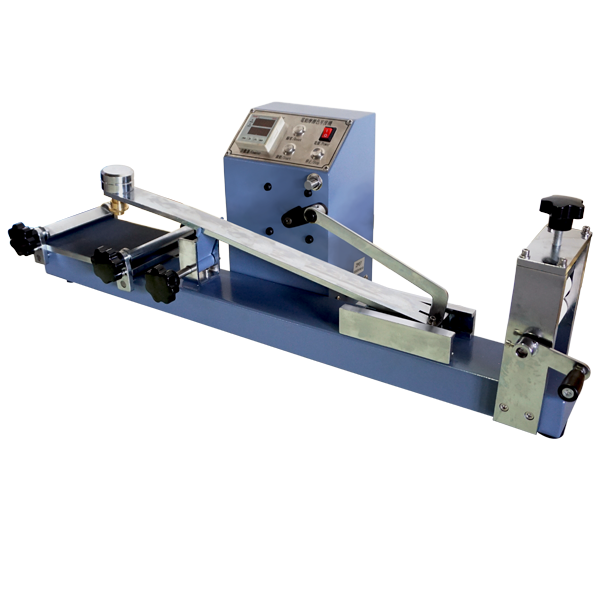

Specimen cutter

Abrading wheel (optional,depends on specimen material)

Weight mount

Wrench

Related Machines

Related Services

-

Training

The professional engineers with rich experience will personally train and provide complete training content. Your operators and developers can learn the technical skills of various material testing machines from novice to expert.

READ MORE

-

Maintenance Service

We provides free maintenance during the warranty period to ensure perfect after-sales service. Our ERP warehousing system makes users quickly obtain the required parts for standing maintenance within 10 years after the sale.

READ MORE

-

Customize Service

The software is self development. R&D team independently develops its own software programs which has high integration capability and scalability to add new analysis items and meet various testing needs.

READ MORE